Our innovative dies, for quality extrusions

Alto Aluminum Tooling has always considered as imperative to improve continuously the performance of its dies. This aim has been achieved and constantly made even better through the internal design of a series of dies having specific peculiarities, suitable for the different profiles to be obtained. The experience gained over many years of activity, combined with technical competence and a recognized ability for problem solving, have allowed the company to design and patent the innovative types of dies that we present you on this page.

Convexdie is a particular die's technology exclusively studied and developed for the extrusion of hollow profiles. Its characteristic is to have the legs of the mandrel with a convex shape that compared to a traditional construction let the die have less surface contact with the billet of aluminium. This typology guarantees a remarkable reduction of the friction between the billet and the die during the extrusion process, this allows the aluminium to reach the die's bearing with a lower temperature compare to a traditional die's construction.

Many benefits have been widely proved from its use: a better surface profile quality, faster extrusion speed, reduction of the defects due to the "bend-effect" on the profiles with a big wall thickness and also an increment of the production per hour.

The benefits are:

Many benefits have been widely proved from its use: a better surface profile quality, faster extrusion speed, reduction of the defects due to the "bend-effect" on the profiles with a big wall thickness and also an increment of the production per hour.

The benefits are:

- Bend-effect reduced: 30% less

- Production/hour: up to 30% more

- Higher extrusion speed

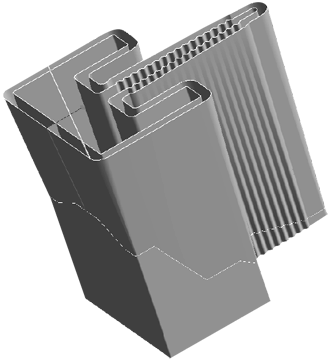

The "Pyramid-die" construction was made in order to extrude profiles called "multi-mandrel" with very small wall thickness, difficult to feed and with limited speed. Its figure is based on the conical bridge that externally is well fixed but then it shrinks in the internal area, allowing to reduce of 30-40%, the mandrel's height compared to a traditional construction.

This cone-shaped, permits a pressure drop-off of the press at least of 20-30 bars, in favour of the profile welding as it's not necessary to make high chambers, which could compromise the core stability during the performance. This method has been successfully tested also on the hard alloys as 7082-7003, where the frictions are extremely strong, it has really maintained unaffected the mechanical requirements. This die's construction guarantees an higher production per hour without compromising the extrusion quality surface.

The benefits are:

This cone-shaped, permits a pressure drop-off of the press at least of 20-30 bars, in favour of the profile welding as it's not necessary to make high chambers, which could compromise the core stability during the performance. This method has been successfully tested also on the hard alloys as 7082-7003, where the frictions are extremely strong, it has really maintained unaffected the mechanical requirements. This die's construction guarantees an higher production per hour without compromising the extrusion quality surface.

The benefits are:

- Work- pressure in extrusion: 20-30 bars less

- Production speed: up to 20% more

- Facilitate the multi-mandrels profiles extrusion

Multi-Step-Dies technology, was born from the development of an American system called "single bearing", for which Alto in 2004 has bought the licence and the software to project, make and sponsor it. The main feature of this technology is the pre-chamber which is subdivided in steps from a minimum of 3 to a maximum of 9. The dies' bearing height normally used is between a minimum of 2mm till to a maximum of 4mm, this allows to reduce their friction of a 50%, as the profile is shaped through the steps. Dropping down to the minimal the friction, we are then in condition to increase the extrusion speed, keeping, anyhow, unaffected the dies' stability.

In case of profiles with very irregular wall thickness, the traditional system due to the dies' bearing difference, emphasizes on the extruded the tonality variation, while, it has been tested, that the Multi-Step-Dies, thanks to their particular structure, reduce this surface defect. Using the same procedure, in this last period Alto makes projects for hollow profiles with the die in MsD technology obtaining remarkable results.

The benefits are:

In case of profiles with very irregular wall thickness, the traditional system due to the dies' bearing difference, emphasizes on the extruded the tonality variation, while, it has been tested, that the Multi-Step-Dies, thanks to their particular structure, reduce this surface defect. Using the same procedure, in this last period Alto makes projects for hollow profiles with the die in MsD technology obtaining remarkable results.

The benefits are:

- Work-pressure in extrusion: at least 30 bars less

- Die's stability increased during the extrusion

- Production speed: up to 25-30% more

Evolution-cut is an innovative technological solution entirely developed from Alto, the Software has been studied to analyze the information such as profile's dimensions, the die's bearings, and the maximal clearance, these data are processed from the Software in order to generate a 3D simulation and its solid model. Thanks to this program's procedure it's possible to recognize the critical erosion areas and this permit to have a maximal die's support and improvement of the surface working area. Evolution-cut applies with brilliant results for all the complex profiles with critical legs and when is required an excellent superficial quality, impressive results also for the well-know problem of the "pick-up".

The benefits are:

The benefits are:

- Max support on the die plate

- Lower presence of shades in the profile

- High quality surface profile

This special die's construction has been developed for the extrusion of hollow profiles, its characteristic is the frontal dropping on the mandrel and the spherical shape of the legs base that hold the mandrel. It's a solution that has been applied firstly for the construction of one-leg dies in order to solve the "bend- effect" on the extruded, later applied with success also for different constructions.

Excellent results have been obtained concerning the reduction of the friction that usually develop the billet due to its passage to the mandrel feeding.

The benefits are:

Excellent results have been obtained concerning the reduction of the friction that usually develop the billet due to its passage to the mandrel feeding.

The benefits are:

- Reduction of the work-pressure in extrusion

- Increment of the extrusion speed

- Better superficial quality of the profile

Are you interested in

these products?

these products?

Are you interested in

our products?

our products?

Are you interested in our products?